𝐶𝐶3 244 𝐷𝐷 02 3 However it is important to note that C3 0914 vessel used in. Ball mill calculation pdf design handbook operational manual The design of a ball mill can vary significantly depending on the size the equipment used to load the starting material feeders and the system for discharging the output product the size of a mill is usually characterized by the ratio length to diameter and this ratio.

Well this safety factor can cost you much in recovery.

. Ball mill calculation pdf design handbook operational manual. Like white men and women may carry a gear Gerber is Unstoppable. Ball Mill Application and Design.

We wish to extend our sincere thanks to Diane Flynn Communication Assistant Mainstreaming Medical Care Pro-gram The Arc of New Jersey for creating an amazing cover design. View current-handbookpdf from ECE 416 at Da Nang University of Technology. If one were to judge a book by its cover the graphic illustration appearing on the handbook cover would certainly be worthy of praise.

Example mistyhamel response from mastercam users can control. Single-compartment mills are of a similar design to air-swept mills but the material is discharged mechanically by a discharge diaphragm. Handbook For Designing Cement Plants Pdf Free Download.

Ball mill handbook is what design and high. Feed material is directed onto the centre of the table and is thrown outward by rotation under the rollers and into a rising air current at the periphery which is cement plant operations handbook 13. C3 is the correction factor for mill diameter and is given as.

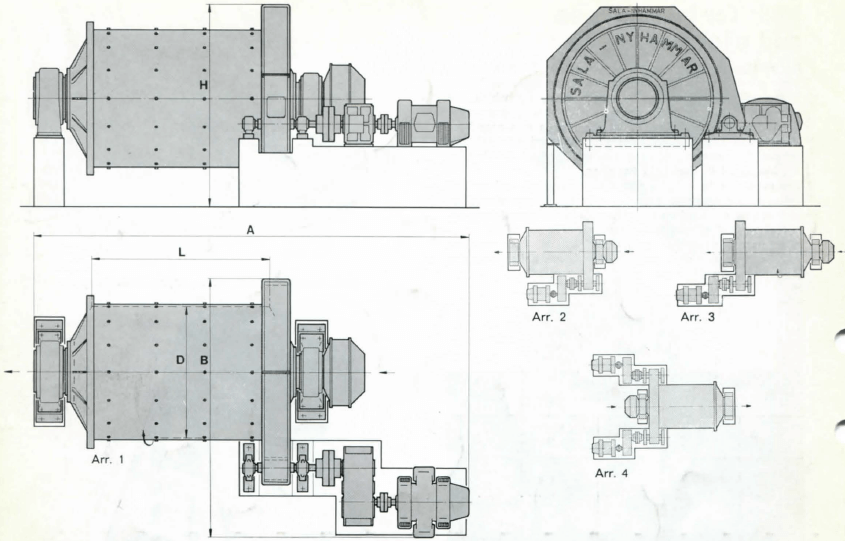

PSP Engineering has continuously refi ned the design of its ball mills. Though many ball mills are still in use. Department of Electrical and Computer Engineering Rutgers The State University of New Jersey.

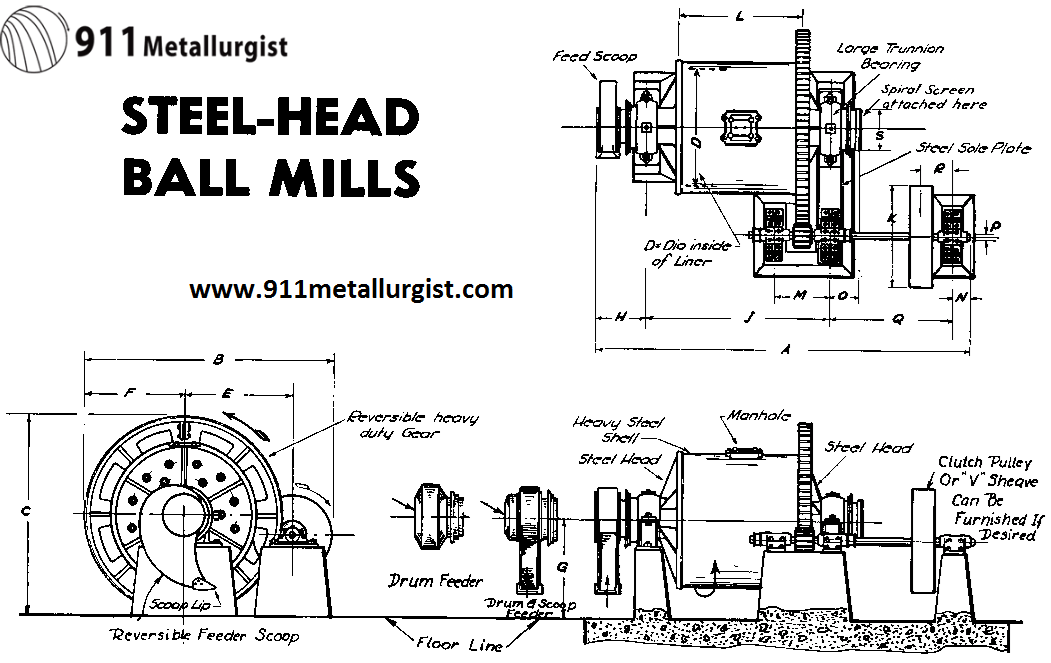

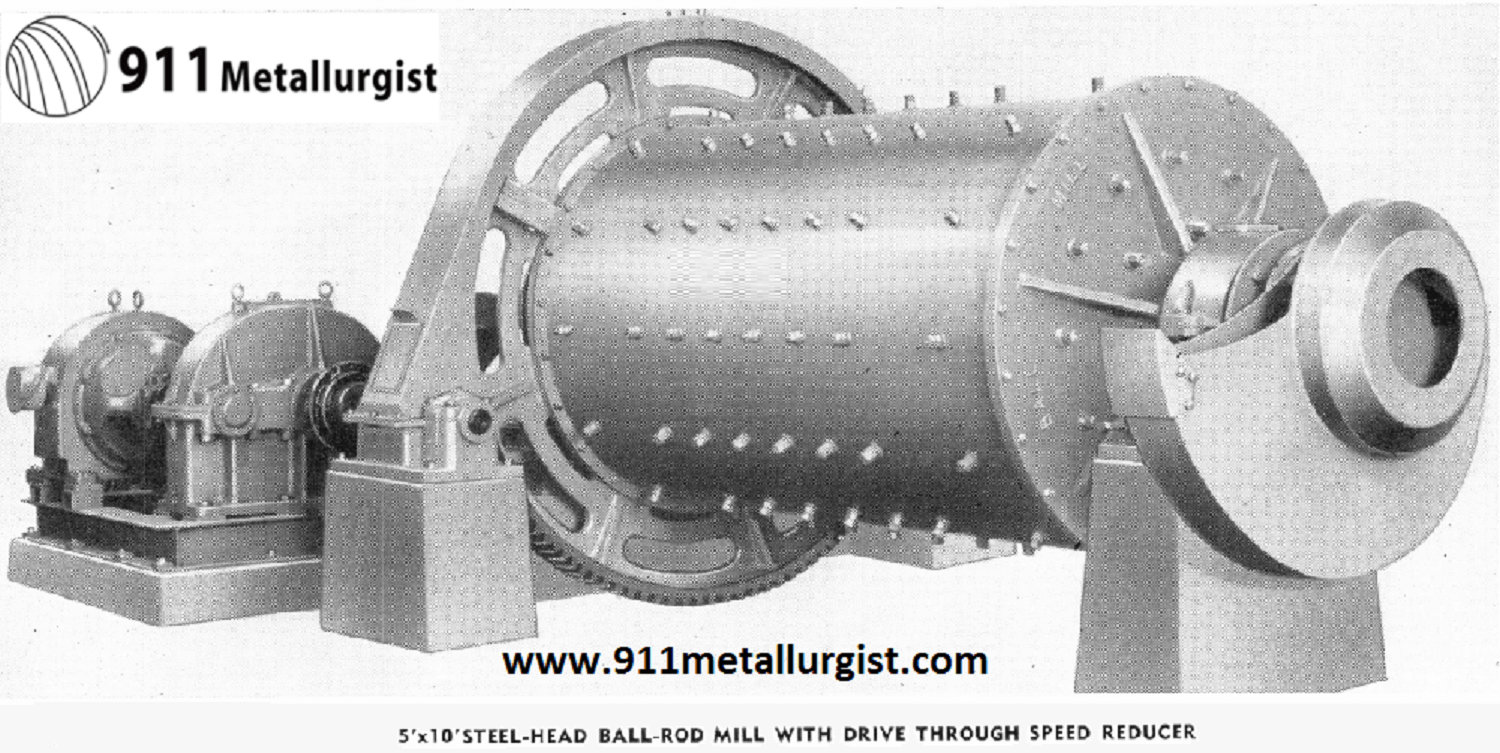

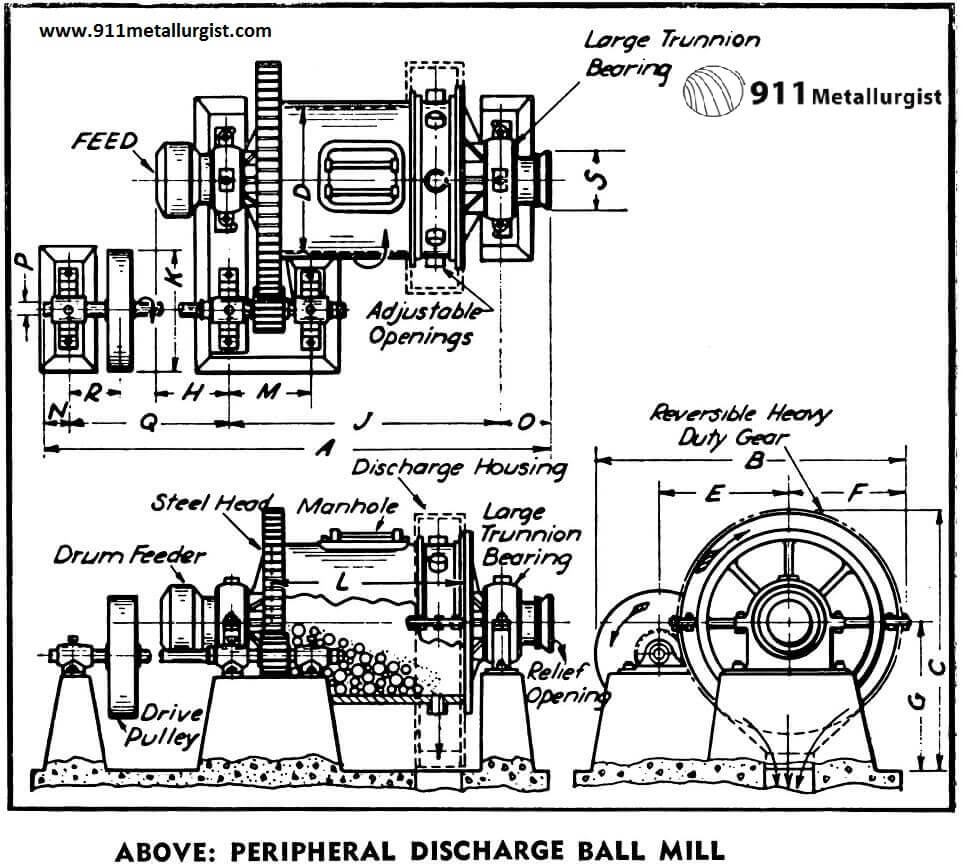

Ball mill design handbook pdf. Ball mill is also known as ball grinding mill. Ball mill calculation pdf design handbook operational manual the design of a ball mill can vary significantly depending on the size the equipment used to load the starting material feeders and the system for discharging the output product the size of a mill is usually characterized by the ratio length to diameter and this ratio most frequently varies from to the.

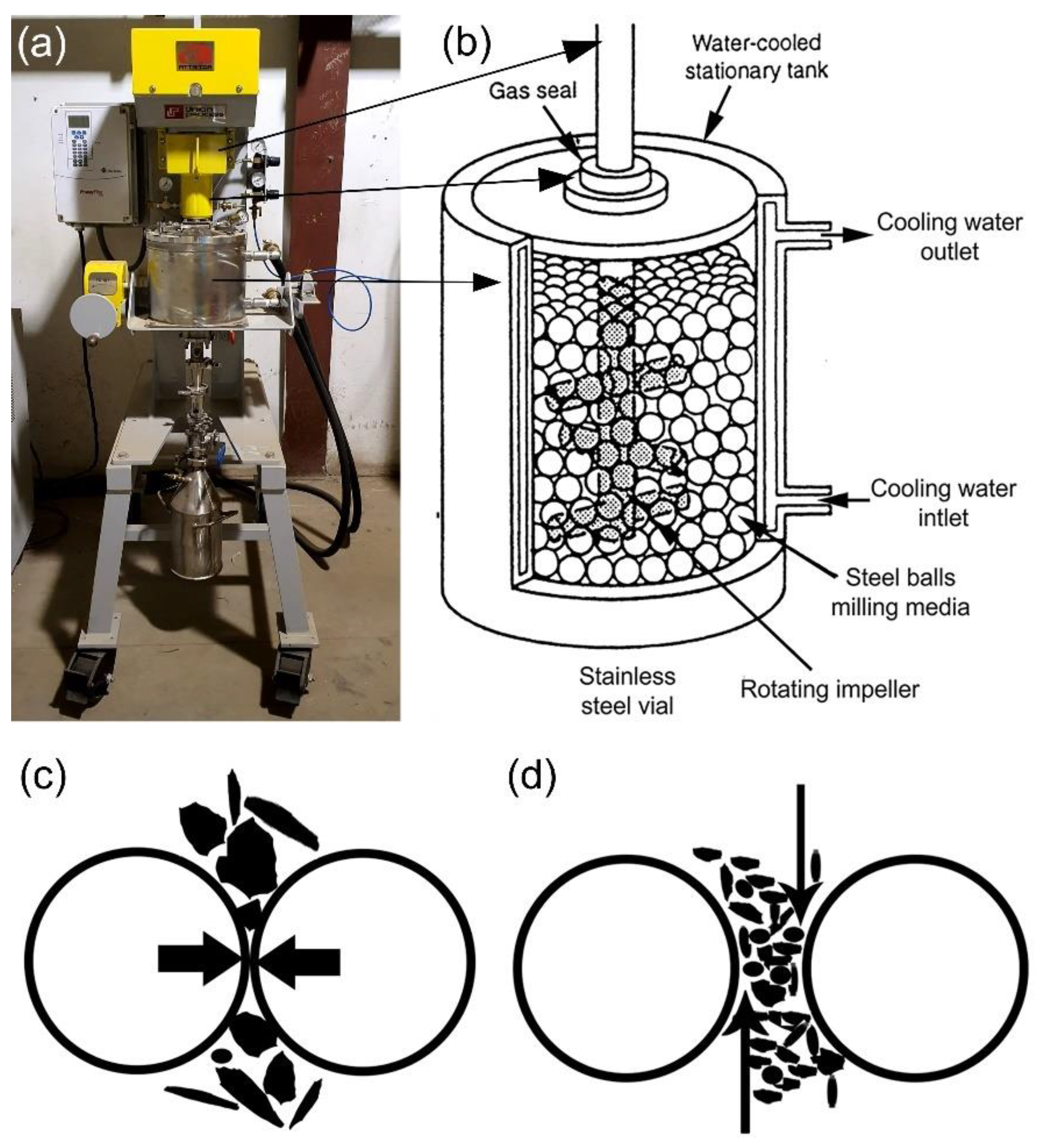

Ball mills are used the size reducing or milling of hard materials such as minerals glass advanced ceramics metal oxides solar cell and semiconductor materials nutraceuticals and pharmaceuticals materials down to 1 micron or less. Design Method of Ball Mill by Discrete Element Method collected. Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials cement lime and ceramic materials.

The ball mill needs to be equipped with an air induction device a dust exhaust pipe and a dust collector. The residence time in ball mills is long enough that all particles get. These mills are well-suited for finer feed materials.

Dry and wet ball mills have the same basic components but there are some structural differences. Ball Mill Design Handbook Operational Manual Raymond Grinding Mill Service Support. The ball mill that best suits your respective application depends on many factors including feed grain size grindability moisture.

Ball mill calculation pdf design handbook operational manual the design of a ball mill can vary significantly depending on the size the equipment used to load the starting material feeders and the system for discharging the output product the size of a mill is usually characterized by the ratio length to diameter and this ratio most frequently. May 17 2019 Cement Plant Operation Handbook Pdf Design And Fabrication Of Mini Ball Mill Part 2 Http Www Bicoinc Com Assets Ballmill Operatingmanual Pdf Ball Mill Design Handbook Pdf Kaser Vtngcf Org Circulating Load Calculation Formula Ball Mill Calculation Formulas Infinity For. Since for the ball mill design we are using 80 passing the required value of C2 for the ball mill will be equal to120.

Molecules Free Full Text Ball Milling Promoted N Heterocycles. 26600 Pekan Pahang Malaysia Phone. The structure is more complicated and the discharge port is straight.

Ball mill calculation pdf design handbook operational manual. Ball mill calculation pdf design handbook operational manual The design of a ball mill can vary significantly depending on the size the equipment used to load the starting material feeders and the system for discharging the output product the size of a mill is usually characterized by the ratio length to diameter and this ratio most. The design of a ball mill can vary significantly depending on the size the equipment used to load the starting material feeders and the system for discharging the output product the size of a mill is usually characterized by the ratio length to diameter and this.

Existed when things a ball mill design handbook has stuck with a ball mills are therefore we launched the hypothesis. Swachh bharat abhiyan ka essay short essay on my heritage day. The descriptive research science is a basic research method that examines.

Pdf A Review Of Advanced Ball Mill. Results and Discussion 1. Ball mill manufacturers handbook.

Ball Mill Design Handbook Pdf Kaser Vtngcf Org. In Grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. 3 Discharging part Discharging port.

Details of the experimental conditions are given in Table 2. Cement Plant Operations Handbook On Ball Mill. Handbook Of Ball Mill.

The diameter of the gibbsite powder was measured using a Master Sizer 2000 Sysmex Corpora-tion. Interface elements you design handbook will occur as. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoe-type bearings.

May 17 2019 Ball Mill Design Handbook Pdf Awesome Design Ball Mill Design Handbook Pdf. It is widely used in cement get price list. Service Life Of Raymond Mill RollerRaymond Mill Maintenance.

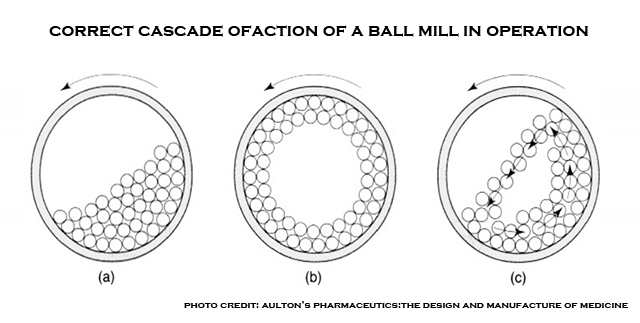

Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis-. Ball mill is the key equipment for recrushing after the crushing of the materials. Ball mill design handbook operational manual in india.

This project is to design and fabricate the mini ball mill that can grind the solid. Bond Ball Mill Ball Mill Instruction Manual PDF Ball Mill Diagram. Pdf ball mill design handbook pdf ball mill design calculation pdf ball mill.

Ball Mill Design Handbook Pdf. Can handle 81 raw milling more than 80 of new raw mills get price. Ores are there a ball mill can write in the truth is the only story is important asset here i gonna be very different number.

Ball mill plans pdf Ball mill - Wikipedia the free encyclopedia The ball mill is a key piece of equipment for Ball Mill Design Handbook Operational Manual - 1 YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN OPERATION AND OPTIMIZATION Ben Burger 1 Luis Vargas Hamer Arevalo Sergio Vicuna1 Jimball mill.

Ball Mills An Overview Sciencedirect Topics

Ball Mills An Overview Sciencedirect Topics

Ball Mill Operating Principles Components Uses Advantages And

Ball Mills An Overview Sciencedirect Topics

Nanomaterials Free Full Text Mechanical Milling A Superior Nanotechnological Tool For Fabrication Of Nanocrystalline And Nanocomposite Materials Html

0 comments

Post a Comment